Global supply chains: Under pressure amid a lack of container ships

Global trade at a record high…

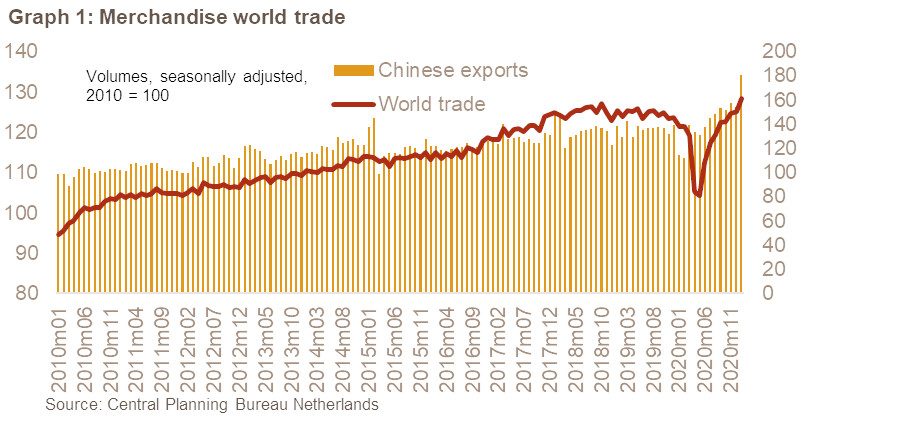

With the sudden stop of the economic activity worldwide, global trade reached last May levels that had last been hit at the beginning of the 2010s. However, it rebounded strongly in the third quarter of 2020 with the boom in e-commerce and thanks to a sustained demand from Europe and the US for medical equipment and electronics out of Asia. In the meantime, China was the first large economic power to resume industrial production. With those trends continuing, volumes of global merchandise trade have reached an all-time high (cf. graph 1).

… hides strain on supply chains

However, those thriving numbers are hiding shipping-related issues, which are currently putting a strain on global supply chains.

A global container shipping shortage is indeed at play since the rising demand for Chinese exports arose at a time when many container ships had been taken out of the market to sustain prices last spring. As a result, since last December, shipping freight rates have been multiplied by three at least on the routes between Asia and Europe or the USA (cf. graph 2). The shortage of seafarers as well as pandemic-related restrictions at ports are delaying the return of ships to Asia and adding to the hindrances and shortages. Last month, the behemoth container ship Ever Given blocking the Suez Canal, through which about 12% of global trade transits, was an additional (although temporary) obstacle, as many ships (container ships, tankers, etc.) were stuck for almost a week and others had to take the longer route through the Cape of Good Hope to transit between Asia and the West, thereby increasing freights. When the giant cargo ship was freed from the Suez Canal, it took several days before the hundreds of ships waiting to cross the Canal could resume their course, implying new delays and congestion at ports.

Regarding the outlook, slower-than-usual operations at ports due to Covid-19-related staffing issues could remain a hurdle with vaccination being particularly slow in the countries from which many seafarers and port workers come from.

Mounting freight rates imply higher commodity prices, from wood to polymers or textile. Textile plants in China have reportedly had to close due to those higher freight costs and delays. But supply chain problems are particularly acute in the semiconductor industry. Shipping issues combined with a huge rise in the demand for computers for homeworking, the February winter storm that hit Texas, paralysing some of the largest chip-making plants, and a fire last March at Renesas Electronics Corporation’s chip factory in northern Japan, one of the world’s largest chip makers for the automotive industry, are creating a huge shortage of those electronic parts, key to all digital devices. Moreover, the record drought and water crisis in Taiwan – a major chip manufacturer worldwide – could affect global chip production as well. The chip shortage has slowed automotive production around the world at a time when demand for the sector has rebounded and threatens to delay output for other forms of electronics, including smartphones. The issue could last at least until the second half of the year.

Analyst: Florence Thiéry – f.thiery@credendo.com